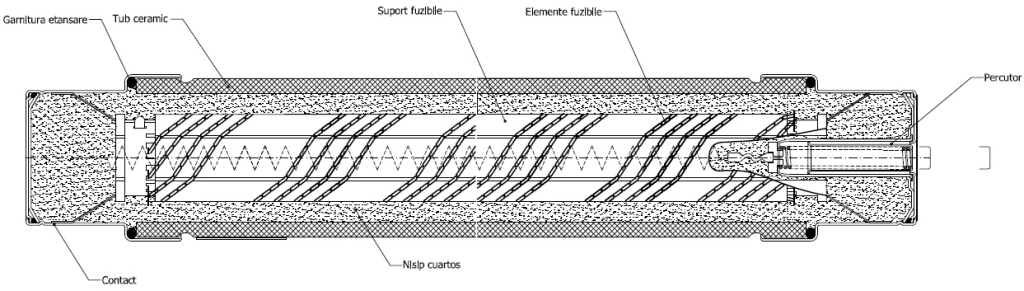

From the outside, a fuse-link seems simple: a ceramic tube with two metallic ends. But inside, every component plays a critical role in safe and precise operation. A high-quality fuse is the result of an exact combination of materials, geometry, and manufacturing technology.

1. Insulating tube (housing)

Made of special ceramic resistant to high temperatures and mechanical shocks.

Role: Provides electrical insulation and maintains mechanical integrity during the internal explosion that occurs during operation.

2. Fuse element (wire or strip)

Manufactured from special alloys of copper, silver, or zinc.

Designed with a specific thickness and shape to melt rapidly at a defined current level.

May consist of several segments connected in series.

Multiple fusible elements can also be connected in parallel within a fuse.

3. Arc-quenching medium (quartz sand)

Very fine, dry, and clean sand compacted under pressure into the tube.

Role: Extinguishes the electric arc formed when the fuse element melts.

The sand absorbs energy and prevents explosion.

4. Metallic end caps (terminals)

Made of copper, brass, or nickel-plated alloys.

Provide electrical contact and enable mounting in the specific holder.

In medium-voltage fuses, special devices may exist for tripping load-break switches with a striker pin.

The current rises above the admissible limit.

The fuse element heats rapidly and melts.

An electric arc forms between the broken ends of the first fusible element. After this arc is extinguished, the next element melts and another arc appears. This sequence continues, with the arc transferring from one element to another until the full arc-quenching length is achieved.

The quartz sand absorbs the energy and extinguishes the arc.

The current is interrupted within milliseconds, without risk to the rest of the installation.

Material & geometry of the fusible elements: alloy type (e.g., silver, copper, zinc), cross-section, notches, and number of elements in series/parallel.

Time–current characteristics: pre-arcing I²t, total clearing I²t, and let-through current/energy matched to the protected equipment.

Arc-quenching medium: sand grain size, purity, dryness, and compaction density inside the tube.

Thermal environment: ambient temperature, enclosure ventilation, grouping of devices, duty cycle, and pre-loading.

Electrical conditions: system voltage (AC/DC), prospective short-circuit current, power factor, and network transients.

Mechanical construction: ceramic tube strength, end-cap material/plating, contact pressure, and mounting alignment.

Installation factors: terminal torque, contact resistance, conductor size, and holder quality/clearances.

Application specifics: motor inrush, transformer magnetizing current, capacitor inrush, harmonics, and cyclic loading.

Standards & ratings: correct voltage, current, utilization category (e.g., gG, aM), and breaking capacity for the network.

Aging & environment: vibration, contamination, humidity, altitude, and thermal cycling over time.

| Factor | Influence |

|---|---|

| Type and thickness of fuse element | Stability and precision of the melting curve |

| Quality of quartz sand | Arc-quenching capability |

| Sealing of the tube | Service life and internal protection |

| Welding and joints | Reliability under dynamic conditions |

| Terminal material | Conductivity and mounting compatibility |

| High-precision manufacturing technology | Overall consistency and safety |

Automatically wound

Point-welded with digital control

Filled with evenly compacted quartz sand

Hermetically sealed

100% tested for appearance and strength

This rigor ensures:

Predictable reaction in case of fault

Long service life in operation

Compatibility with all equipment in the network

Fuse-links are more than just “tubes that burn out.” They are high-precision technical components, designed to protect valuable equipment and entire networks.

CNC LTD is a Romanian manufacturer of medium-voltage fuses, offering ISO-certified quality and proven reliability for energy utility companies worldwide.